Understanding Industry Production Standards for the Best Coffee Robot Arm in Your Cafe

In today's competitive cafe landscape, understanding industry production standards is crucial for selecting the best Coffee Robot Arm to enhance efficiency and customer satisfaction. A recent report by the International Coffee Organization revealed that global coffee consumption has exceeded 170 million 60-kilogram bags annually, highlighting the increasing demand for high-quality coffee. As cafes strive to improve their service speed and consistency, integrating advanced robotics technology has become essential.

According to a study by the National Coffee Association, nearly 60% of consumers prioritize quality and experience, making it vital for cafes to adopt innovations like Coffee Robot Arms. These robotic systems not only ensure precise brewing techniques but also offer the ability to streamline operations, reduce labor costs, and maintain hygiene standards in coffee preparation. Embracing such technology while adhering to industry standards is the key to thriving in today's coffee market.

The Rise of Coffee Robot Arms: What to Expect by 2025

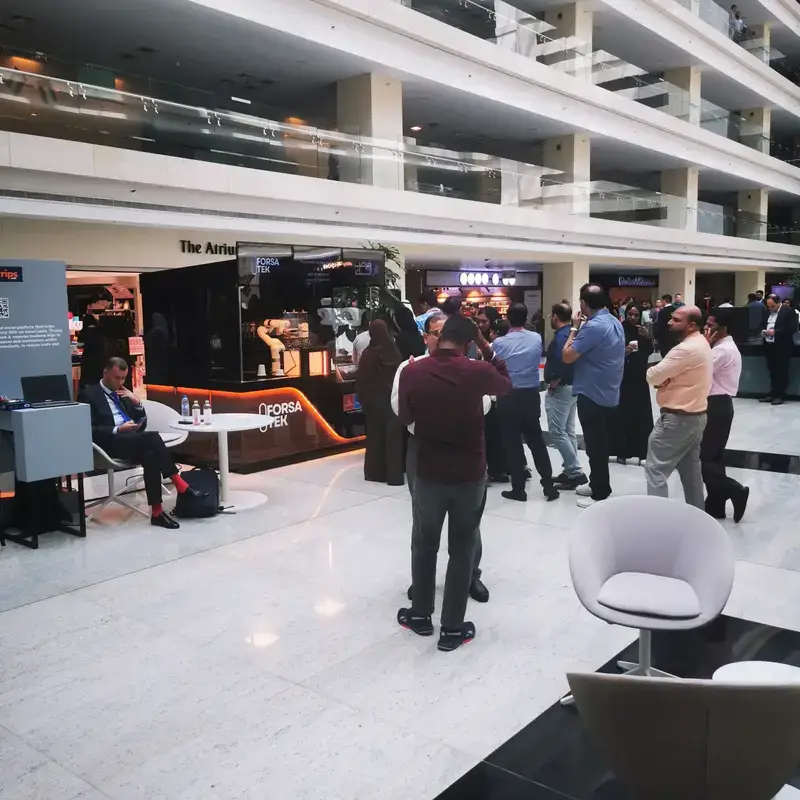

As we approach 2025, the coffee industry is witnessing a significant transformation with the rise of coffee robot arms. These innovative machines are not only streamlining the coffee-making process but also enhancing customer experience in cafes. The recent launch of an automated drive-thru café exemplifies this shift, demonstrating how technology can deliver beverages to customers in under 30 seconds. This rapid service is becoming increasingly essential as consumer expectations rise, setting the stage for more cafes to invest in robotic solutions.

Moreover, the collaborative robot market is projected to see substantial growth, with expectations to reach USD 3.38 billion by 2030. This surge is fueled by advancements in robotics technology, which is enabling cafes to operate more efficiently. As we embrace automation in coffee preparation, businesses will need to align with industry production standards to ensure that they harness the full potential of these robotic systems. By 2025, we can expect to see a wider adoption of coffee robot arms, significantly reshaping how cafes function and how coffee is served to eager customers.

Key Industry Production Standards for Coffee Automation

As the coffee industry embraces automation, understanding key production standards is essential for ensuring consistent quality and efficiency in cafe operations. According to a recent report by the National Coffee Association, approximately 63% of Americans drink coffee daily, highlighting the need for reliable and high-performance coffee equipment. The Coffee Quality Institute emphasizes that adherence to standards such as ISO 9001 can improve product quality and operational efficiency, allowing cafes to meet customer expectations while maintaining profitability.

Another important production standard to consider is CE certification, especially for equipment used in Europe. This certification reflects compliance with health, safety, and environmental protection standards. For instance, a coffee robot arm equipped with CE certification not only ensures that it meets rigorous safety standards but also fosters consumer trust in automated coffee solutions. Considering that according to IBISWorld, the coffee shop industry is projected to grow with a market size of $45.4 billion in 2023, investing in high-quality, compliant robotic equipment becomes paramount for businesses looking to stay competitive in this ever-evolving landscape.

Innovative Solutions for Enhancing Coffee Quality with Automation

In recent years, the coffee industry has witnessed a significant transformation with the incorporation of automation technologies, particularly robotic arms that are designed to enhance coffee quality. According to a report by Allied Market Research, the global coffee machine market is projected to reach $9.5 billion by 2027, driven largely by innovations in automation. These robotic solutions not only streamline production but also ensure consistency in taste and presentation, which are critical for maintaining customer satisfaction in cafes.

Automated coffee systems equipped with advanced robotics have been shown to improve precision in brewing parameters. For example, a study from the Specialty Coffee Association highlights that automated machines can maintain temperature variance within a range of +/- 1°C, a crucial factor in the extraction process that influences the flavor profile of the coffee. Furthermore, robotic arms can replicate complex latte art designs consistently, elevating the aesthetic appeal of beverages and enhancing the overall customer experience. By adopting these innovative solutions, cafes can not only optimize their workflow but also deliver a premium quality coffee experience that meets the evolving expectations of consumers.

Navigating Challenges in Integrating Robot Arms into Cafe Operations

Integrating robot arms into cafe operations can be an exciting yet challenging endeavor. While these advanced machines promise efficiency and consistency in coffee preparation, the transition from traditional methods to automation requires careful planning. One major challenge is ensuring that the robot arm can replicate the nuanced techniques of skilled baristas, such as frothing milk to perfection or creating intricate latte art. A thorough understanding of production standards is essential; without it, cafes may struggle to meet their quality expectations, risking customer satisfaction.

Another significant hurdle lies in the integration of robot arms with existing cafe workflows. Ensuring smooth communication between the robot system and other operational elements—like order processing and inventory management—requires substantial investment in technology and staff training. Employees must be equipped to work alongside these machines, understanding both their capabilities and limitations.

By effectively navigating these challenges, cafes can harness the power of automation, elevating both their service efficiency and overall customer experience. Embracing such innovations while maintaining the essence of handcrafted coffee will be vital for long-term success in the competitive cafe landscape.

Future Trends: The Impact of AI on Coffee Robotics and Customer Experience

The integration of artificial intelligence (AI) into coffee robotics is reshaping the café industry, enhancing both operational efficiency and customer experience. According to a recent report by Market Research Future, the global coffee robotics market is projected to reach $1.5 billion by 2025, driven by significant advancements in AI. Coffee robots equipped with machine learning algorithms can analyze customer preferences, enabling personalized beverage recommendations and improving service speed. This dynamic not only addresses the increasing demand for customization but also boosts customer satisfaction.

Moreover, AI-driven coffee robots are transforming the way cafes manage their operations. Research from the International Coffee Organization indicates that automation can reduce labor costs by up to 30%, allowing café owners to allocate resources more effectively. By utilizing predictive analytics, these robots can optimize inventory management, ensuring that popular coffee beans and supplies are always available while minimizing waste. As AI technologies continue to evolve, the potential for integrating smart coffee solutions—such as voice command ordering and real-time feedback channels—will further enhance the café experience, positioning establishments at the forefront of innovation in the industry.