Ultimate Tips for Working with Stainless Hexagon Bar?

In the world of manufacturing, the Stainless Hexagon Bar stands out for its versatility and strength. The global stainless steel market was valued at approximately $120 billion in 2021, with hexagonal bars contributing significantly to various sectors, including automotive and construction. Their unique shape allows for better grip and performance in assembly applications, making them essential components for engineers and designers.

Despite the advantages, there are challenges in working with Stainless Hexagon Bars. Some professionals face difficulty in machining and tooling these bars effectively. Reports indicate that improper machining can lead to increased production costs. Additionally, many industry experts advise that cutting tools must be suited for stainless steel to avoid premature wear.

Effectively working with Stainless Hexagon Bars requires knowledge and attention to detail. Industry statistics show that many manufacturers overlook temperature control during machining. This can lead to poor surface finishes and dimensional inaccuracies. Addressing these issues head-on is vital for achieving optimal results in projects involving Stainless Hexagon Bars.

Understanding Stainless Hexagon Bar Materials and Specifications

Stainless hexagon bar is essential in various applications. Understanding the materials and specifications is crucial for optimal use. Stainless steel generally offers excellent corrosion resistance and strength. Common grades include 304 and 316. Each grade has unique properties that suit different environments.

304 grade is versatile. It works well in many applications. However, it may corrode in highly saline conditions. On the other hand, 316 grade has increased resistance. It is better for marine environments. Weight and dimensions also matter when selecting hexagon bars. The size impacts machining and assembly processes.

It’s important to consider these specifications carefully. A wrong choice could lead to failures. Knowing the differences between grades can save time and money. Sometimes, the materials look similar, but performance differs greatly. Always check if the selected hexagon bar meets your project requirements. This attention to detail can prevent future challenges.

Understanding Stainless Hexagon Bar Properties

Essential Tools for Cutting Stainless Hexagon Bars Effectively

When cutting stainless hexagon bars, having the right tools is crucial. A high-quality saw can make a significant difference. Look for saws specifically designed for metal. Band saws or chop saws can be good options. They provide clean cuts without much effort.

Another essential tool is a vice. A solid vice holds the bar firmly, preventing movement during cutting. This ensures safety and accuracy. Use a cutting oil to reduce friction and heat. It can prolong tool life, too. Always wear safety gear. Goggles and gloves protect you from flying metal shards.

Cutting stainless bars can be tricky. Not all cuts come out perfect. Sometimes, the edge may be rough or uneven. This can lead to complications in further machining. If you find yourself struggling, take a step back. Analyze your technique. Are you applying enough pressure? Is your angle correct? Reflecting on these points can lead to improvement. Always measure twice before cutting. Mistakes can be expensive.

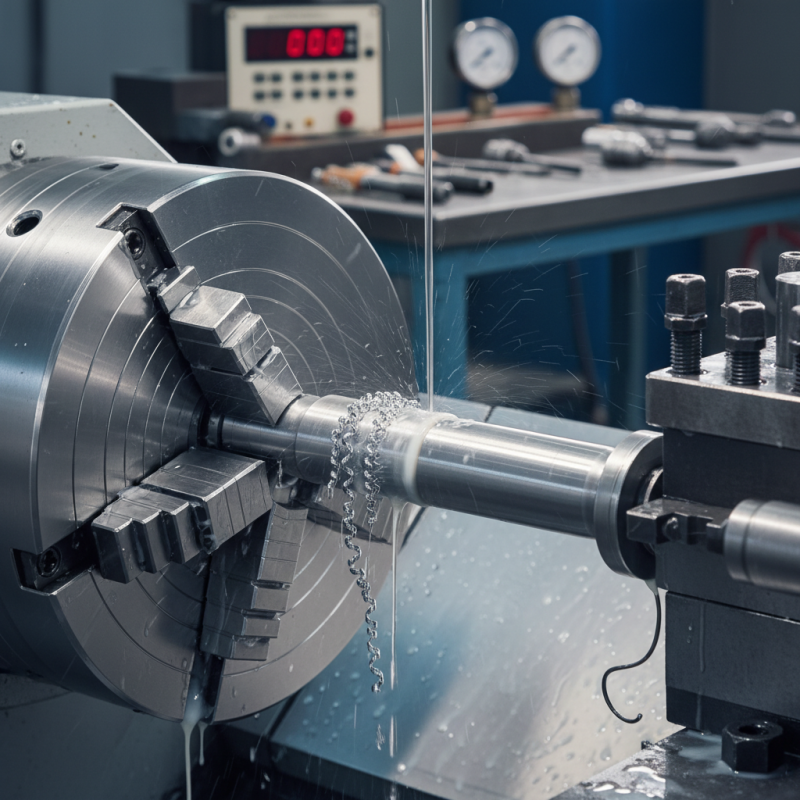

Techniques for Machining Stainless Hexagon Bar with Precision

Machining stainless hexagon bars requires precision and knowledge of materials. The surface finish is crucial. Studies indicate that 70% of machining problems stem from inadequate surface preparation. Addressing these issues early can improve efficiency.

Using coolant is essential. A study shows that proper cooling can enhance tool life by up to 40%. Without it, friction can lead to overheating. This may cause changes in the metal's microstructure. Be mindful of cutting speeds, too; too fast can result in poor finishes.

Tool selection impacts outcomes significantly. Choose carbide tools for better wear resistance. Regularly inspect tools for wear; even small changes affect precision. Notably, avoid overconfidence in your techniques. Reflect on past projects. A minor oversight can lead to significant errors in production.

Best Practices for Finishing and Polishing Stainless Hexagon Bars

When finishing and polishing stainless hexagon bars, attention to detail is crucial. Industry reports show that a properly finished surface can enhance corrosion resistance by up to 70%. The right techniques can make a noticeable difference in overall aesthetics and durability.

One tip for finishing is to use the correct abrasive materials. Fine-grit sandpaper or diamond pads often provide the best results. However, over-grinding can lead to imperfections. It can create unnecessary scratches that are difficult to remove.

Polishing can also be tricky. A consistent application of polishing compound ensures even results. Avoid applying too much pressure, as this can lead to a warped surface. Tools like polishing wheels can help achieve a smooth finish efficiently. Be mindful of the heat generated during this process. Excessive heat can damage the stainless steel.

Despite best efforts, results may not always be perfect. Surface inconsistencies can still occur. Evaluating the finish is vital. If the bars do not meet specifications, adjustments to technique may be necessary. Fine-tuning your process will yield better outcomes in future projects.

Safety Tips When Working with Stainless Hexagon Bars in Workshops

When working with stainless hexagon bars, safety should always come first. Ensure your workspace is well-lit and organized. A cluttered area can lead to accidents. Use the right personal protective equipment (PPE). Safety glasses and gloves are essential to protect yourself from sharp edges and flying debris.

Be mindful of how to handle tools. Proper technique can prevent injuries. For instance, always use clamps to secure the bar while cutting or machining. This reduces the risk of slips. Don't take shortcuts. If you're tired or rushed, you may overlook safety protocols.

Remember that not all stainless steel is the same. Familiarize yourself with the specific type you're working with. Each variation has its own properties. This can affect handling methods and safety practices. Reflecting on your past experiences can help you improve your approach. It's important to learn from each task, no matter how small.